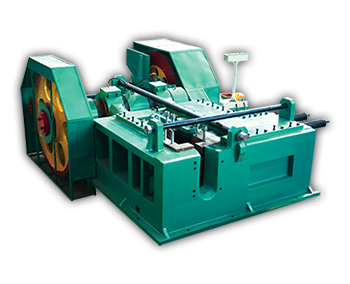

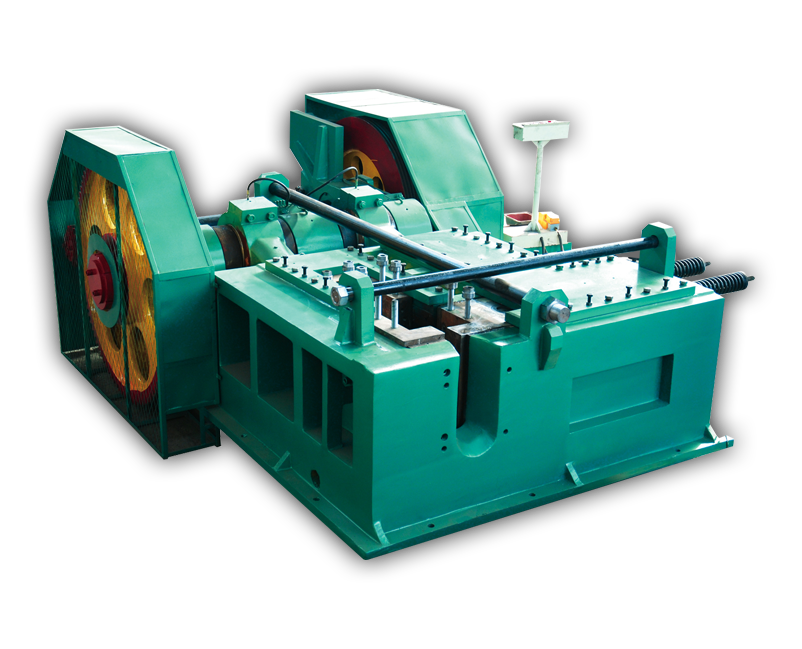

SJD10-500T vertical split die flat forging machine

Category: SJD10 Series

·The machine adopts an integral structure with good rigidity and high precision.

·Adopting combined pneumatic friction clutch-brake and imported safety double valve control, which is sensitive in action, safe and reliable

·The electrical control adopts imported PLC centralized control, and the automatic interface is reserved

·With inching, single, continuous, emergency stop operation. The mold position and clamping force can be adjusted manually;

| SN | Project Name | Unit | Technical Parameters |

| 1 | Nominal Force | kN | 5000 |

| 2 | Nominal Force Stroke | mm | 12 |

| 3 | Slider Stroke | mm | 280 |

| 4 | Slider Stroke Cycle | s.p.m | 45 |

| 5 | Clamping Slider Stroke | mm | 125 |

| 6 | Distance from the Front Dead Center of the Forging Slider to the Edge of the Die | mm | 110 |

| 8 | Stroke after Mold Closing * Stroke before Mold Opening | mm | 190*45 |

| 11 | Mold Dimensions (Length * Width * Depth) | mm | 450*180*435 |

| 12 | Feed Window (Width * Depth) | mm | 150*2400 |

| 13 | Motor Power | kW | 45 |

| 14 | Overall Dimensions (Front-Back * Left-Right * Height) | mm | 4600*3100*1860 |