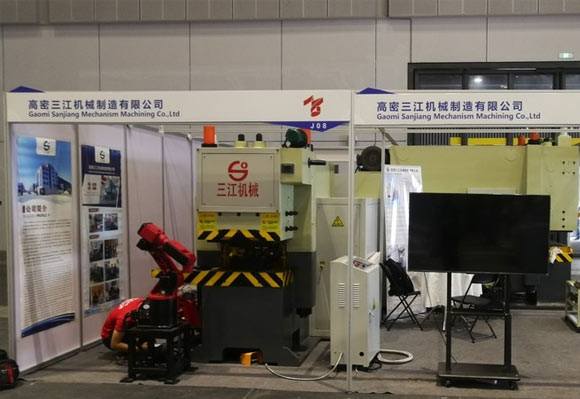

How to carry out precision forging for flat forging machine equipment

During the production of flat forging machine equipment, an important point is the production of precision forging equipment. In particular, high-precision forging parts must be realized by using high-quality production tools and skilled technicians. At this time, the use of flat forging machine can well realize the production and processing of above high-precision forging parts. Flat forging machine

So in the process of die forging parts processing and production, how can we better manufacture excellent and high-precision forging parts? Next, let's answer the questions in detail. Flat forging machine

In fact, in the processing and manufacturing process of high-precision forged parts, the specific raw tea manufacturing process is as follows: in the production, the raw materials should be fully cut first, which mainly acts on the following raw tea processing process, that is, what we usually call heating, size, forging, and production pretreatment, cleaning and testing. In the whole process, the production requirements of the flat forging machine are also. In addition, the functions of the flat forging machine equipment can well adapt to the production of high-precision equipment. In addition, the innovation and application of high and new technology can well realize the production and processing of high-precision forging die equipment components. Flat forging machine

In addition, the production of high-precision forging die parts is that after the flat forging machine equipment uses machinery to exert a certain amount of pressure on the metal embryo material in the forging process, the material produces plastic deformation to produce certain changes in mechanical properties, shape and size, so as to realize the production of products.