Experience of visiting 2021 China International Metal Forming Exhibition

I don't know when, people regard the scale of the exhibition as an important indicator of the level and success of the exhibition! The probability is after the exhibition becomes the exhibition economy!

Zhang Jin, Secretary General of China Forging Association

Can large scale really reflect the current situation of the industry and the level of the exhibition? From this metal forming exhibition, the invisible scale can reflect the situation of the industry! Small scale can also reflect the truth.

Affected by the epidemic situation, some large exhibitors did not rent large booths, and some enterprises were absent, but this did not lose the purpose of the exhibition or affect the role of the exhibition. This exhibition is also:

Reflects the prosperity of the industry - understand what's wrong with the industry;

Reflects the industry's attention - what are the industry's hot spots?

Reflects industry trends - what is the future outlook?

Reflects industry weaknesses - what is creating opportunities?

From the exhibits displayed on forgings, China's forging production level has been greatly improved. So far, China's forging industry can produce forgings of various shapes and materials, and the forging accuracy has been greatly improved. Enterprises with characteristic products (product specialization) survive well, and some enterprises have reached the international level in production technology. At present, the forging industry is most concerned about how to improve the per capita sales and labor production efficiency. Automation has become an important hot spot, and the die surface treatment and die surfacing technology have been further promoted. The biggest weakness of the whole industry is that the application of forging process simulation software is not popularized and in-depth, and there are misunderstandings in the cognition of automation, digitization and informatization.

From the forging equipment on display, the production of forging equipment in China has further developed. The main engine is still dominated by electric screw press, supplemented by hot die forging and electro-hydraulic hammer. Fortunately, the production of new flat forging and small radial forging machines has also appeared to meet the needs of different process production. In the field of hydraulic press forging, it covers almost all aspects and has made great progress. Forging equipment has made phased progress in the future. Forging equipment production mainly needs to establish the forging equipment manufacturing concept of "no major defects, no minor defects".

From the exhibition of stamping parts, stamping parts adhere to the production concept of "precision, accuracy and beauty". Precision - dimension is becoming more and more precise, and quasi - geometric tolerance is becoming more and more accurate. Beauty - stamping parts have the pursuit of beauty in terms of modeling and surface quality. This is a trend reflected by the product. In addition, it can be seen that with the development of automobile industry and various stamping parts consumption industries, in addition to processing traditional plates, the forming of aluminum plates, high-strength plates, composite plates and other materials will be greatly developed. The digitization of stamping production, high-speed and low-cost on-line detection, and the research of material forming machinery are the highlights of the development of stamping technology in the future.

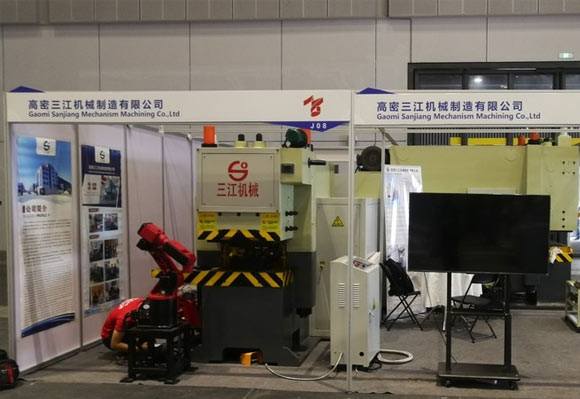

From the stamping equipment on display, the stamping equipment has made great development. It has not only its own servo stamping machine production system, but also the production achievements of domestic servo motors and servo functional parts, which is not a small progress. Important progress has been made in the manufacturing of continuous die stamping, high-speed stamping and progressive die stamping equipment, and continuous progress has been made in the traditional press. Due to its special structure and the improvement of its manufacturing level, the application field of open punch continues to expand. Some enterprises not only produce open punch, but also produce small forging press. The press with this structure is easy to realize the automatic production of small stamping parts and forgings.

From the exhibits on display, the processing level of sheet metal parts has been greatly improved, and significant progress has been made in the production of small sheet metal parts. Some production has been unattended. At the same time, it is also developing from sheet metal production to automatic assembly of finished products. Significant progress has been made in laser cutting. Generally, the cutting thickness of carbon steel plate can reach 450mm, and the cutting of pipe fittings and profiles has been completely successful. From the perspective of sheet metal product category, there are no sheet metal parts that can not be made in China, and some enterprises have also started "service manufacturing" to participate in the product development of users. At present, the standardization of sheet metal parts is still a blind spot, especially for sheet metal parts used in some electronic and electrical manufacturing industries, it is necessary to carry out standardization; The theoretical system and cultural system of sheet metal forming need to be developed and improved.

From the exhibition of sheet metal manufacturing equipment, China can produce almost all kinds of sheet metal processing equipment, which has broken the foreign monopoly, and some sheet metal processing equipment have reached the international level. This sheet metal equipment exhibition lacks several large foreign companies, but this has not affected the exhibition level of exhibition equipment. Some popular technologies or equipment concepts in foreign developed countries are reflected in this exhibition, which is the main development direction of China's sheet metal manufacturing equipment manufacturing industry. The consumerism of laser cutting machine, the automation of bending machine, the limitation of NC punching speed, and the continuous improvement of complete sheet metal processing center are also highlighted in this exhibition. During the exhibition, some sheet metal processing auxiliary equipment also showed good performance, which concentrated on the hot spots, difficulties and focus of the whole sheet metal industry.

The content of metal forming dies is set in the second year of the metal forming exhibition, and there are few exhibitors. However, from the perspective of some products and introductions on display, there have been breakthroughs in forging, stamping dies and sheet metal manufacturing tooling. Some die surface treatment technology displays reflect the development direction or development trend of dies. The "zone and layer surfacing" technology of forging dies, Stamping die surface strengthening and stamping part surface quality optimization technology, as well as the "intelligence" trend of sheet metal manufacturing tools and dies is obvious. The mold is no longer just a mold, but a "high precision and high performance" machine.

The content of plate connection and welding is also listed separately in the metal forming exhibition in the second year, and there are not many exhibitors. However, from the perspective of some products on display, plate connection and welding have also made significant progress, especially the laser cold welding technology. Great progress has also been made in punching welding and laser welding in protective atmosphere. At present, welding automation is still the biggest difficulty.

In any case, there are many outstanding highlights in this exhibition. Although some enterprises are absent from the major event of the industry - "September Festival" for one reason or another, it does not affect the actual landscape, future trends and problems of the industry reflected in the event.

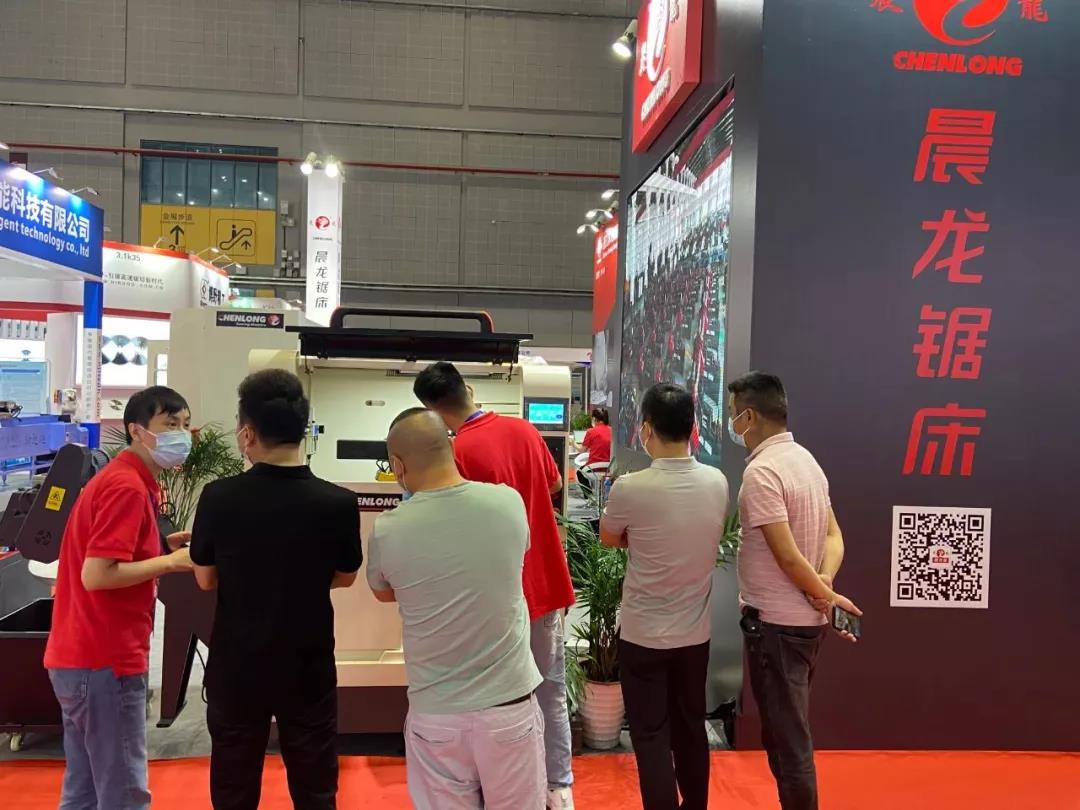

During the exhibition, you can also see many technologies and products supporting forging, stamping, sheet metal production, metal forming die and connection welding production. You can use "ingenious" to describe these technologies and products, such as sawing. There are not only high-speed sawing of metal, but also sawing of plates in metal production (steel structure processing) And mold and tool manufacturing industry, some can replace wire cutting and flame cutting, and in some cases can also replace laser cutting.

Combined with the current metal forming exhibition, forging Conference (die forging factory director meeting), stamping Conference (stamping factory director meeting) and sheet metal manufacturing Conference (sheet metal factory director meeting), China's forging, stamping and sheet metal manufacturing industry is overcoming the long-standing situation of "scattered, disordered and poor" and making rapid progress in the direction of "differentiation, high efficiency and high quality".

In some enterprises, the per capita output value is still relatively low, the product differentiation is not enough, the characteristics are not obvious, and the new innovation of old products is not enough. In terms of equipment manufacturing, attention to details is not enough, and "ingenuity and reliability" are not in place, which needs to be further developed and promoted.