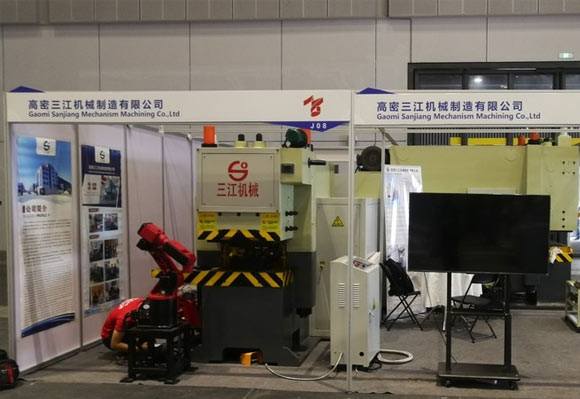

SJD11-75T horizontal split die flat forging machine

Category: SJD11 Series

·The fuselage adopts steel plate welding structure, and the upper and lower fuselages are pre tightened by tensioning bolts. The whole machine has high strength and high stiffness;

·The slider adopts lengthened guide rail, with high guiding precision and strong stability;

·It adopts high-performance dry pneumatic friction clutch brake and imported safety double valve control, with sensitive action, rapid response, safety and reliability;

| Technical Parameters Model | Unit | SJD11-75 |

| Nominal forging force | kN | 750 |

| Nominal clamping force | kN | 850 |

| Nominal force stroke | mm | 5 |

| Upsetting forging slider stroke | mm | 152 |

| Number of trips | Times/min | 90 |

| Clamping slide stroke | mm | 100 |

| Standard die size (left and right * front and rear * thickness) | mm | 240*210*100 |

| Maximum die size (left and right * front and rear * thickness) | mm | 325*235*100 |

| Height of clamping mold center from ground | mm | 850 |

| Punch seat mounting slot size (left and right * height * front and rear) | mm | 260*100*220 |

| The distance between the front dead center of the upset slider and the edge of the die | mm | 100 |

| Main motor power | kW | 7.5 |

| Stroke after mold closing*Stroke before mold opening | mm | 75*33 |

| Lubrication pump motor power | kW | 0.55 |

| Dimensions (length*width*height) | mm | 2500*1750*2300 |

Application scenario:

75t to 250t flat forging machines can be used for local upsetting, punching and shaping of small and medium-sized long rod forgings. They are widely used in automobile, electric power, hardware tools, medical devices and other fields, such as socket wrenches, screw rods, hexagon socket bolts, human joints and so on.

Working conditions of sjd11 flat forging machine:

1. The wire power supply of the flat forging machine is three-phase four wire system, 3-380v 50Hz

2. Allowable fluctuation value of power supply ± 10%

3. Allowable fluctuation value of power frequency ± 1%

4. The flat forging machine must be safely grounded with a separate cable, and the grounding resistance shall be less than 4 ohms.

5. When the flat forging machine is used, the ambient temperature range is 10-40 ℃, the relative humidity is 40-75%, the atmospheric pressure is 86-106kpa, the dust concentration in the air shall not be greater than 10mg / m3, and there shall be no acid, salt and corrosive gas.

6. The flat forging machine shall be installed with firm foundation and good brightness in the workshop.

Note: the above parameters are the standard parameters of sj36 horizontal forging machine of the company. Some parameters can be adjusted according to customer needs to meet user needs!

Local close-up of 75t flat forging machine