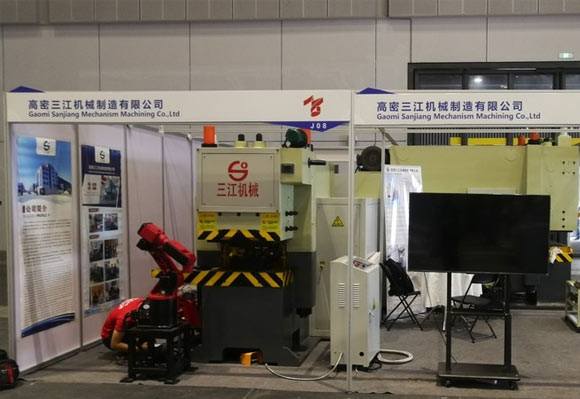

On Sanjiang machinery, a flat forging machine manufacturer what are the characteristics of the die forging process of the flat forging machine

Generally, the flat forging machine has some working characteristics of the hot die forging press, that is, it works under static pressure and is borne by the frame itself; The slider stroke is certain; Good guiding device, etc. This kind of equipment can be applied and developed because it also has the following working characteristics:

1) There are two parting surfaces;

2) The main slider moves in the horizontal direction;

3) Positioning device with blank.

Due to the above working characteristics of the flat forging machine, its die forging process and die design will have the following characteristics:

1) It can forge forgings with concave blocks in two different directions, such as reverse gear, etc;

2) It is convenient for die forging of long rod forgings and long rod hollow forgings, as well as deep punching and deep perforation processes;

3) The die forging slope is small, or the die forging slope is not required, so that the forging is closer to the shape of the part, saving metal and machining time; Flat forging machine

4) It can carry out joint processes such as trimming, shearing, bending and hot fine pressing without additional press;

5) The horizontal split die flat forging machine can carry out hot extrusion process; Flat forging machine

6) The long bar can be used for multi piece die forging to save the labor of bar shearing;

7) The required molds can be combined and inlaid to reduce the consumption of die steel;

8) During flat forging, the vibration and noise are small, the working conditions are good, and it is easy to realize mechanized operation;

9) The impact force of the flat forging machine is small, the equipment foundation is small, and the plant cost is low.