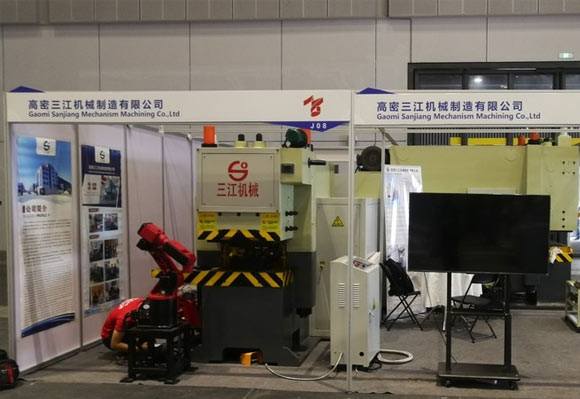

The flat forging machine manufacturer introduces the structure and working principle of the flat forging machine

Flat forging machine is an end forging machine for upsetting bar and pipe in horizontal direction. The flat forging machine has three kinds of motion mechanisms. The punch (punch) moves back and forth in the horizontal direction. Generally, 4 ~ 6 Die bores can be set for the forming mechanism of upsetting processes such as accumulation, upsetting, punching and flanging. It is also the main force application mechanism. Movable female die: it can be opened and closed up, down or transversely to clamp long bars and bear the upsetting force at the end. Cutting mechanism: used to separate forgings from long bars. All flat forging machines are driven by crank slider mechanism. Due to the large processing workpiece and large upsetting force and clamping force, the machine needs to have sufficient stiffness to ensure the accuracy of flat forging.

Before the flat forging machine is started, the bar material is placed in the die chamber of the fixed die and positioned by the front fixing plate to determine the length of the deformed part of the bar material. Then, press the foot pedal to make the clutch work. The crank cam mechanism of the flat forging machine ensures that it works in the following order: during the advance of the main slider, the side slider drives the movable die to quickly clamp the bar, the front material plate retreats, the punch contacts the hot blank and causes it to produce plastic deformation until the die chamber is filled. When the machine returns, the movement sequence of each part is: the punch exits from the die, the movable die returns to its original position, the punch returns to its original position, and the forging is taken out of the die.